Introducing Our Advanced

Mainline Crawler

A Breakthrough in Mainline Inspection

Mainline Crawler

Sewer Inspection: A Quantum Leap.

iPEK brings you rugged, versatile, and quality inspection solutions for your mainline inspection needs. Meet the grueling needs of your inspection operations with our advanced mainline crawlers.

- Unmatched Range: Go where no sewer camera has gone before!

- Maneuverability: Navigate complex systems with ease.

- Adaptability: Save time with quick changeover and minimal tools in the field.

- Intuitive: Control effortlessly with our touchscreen.

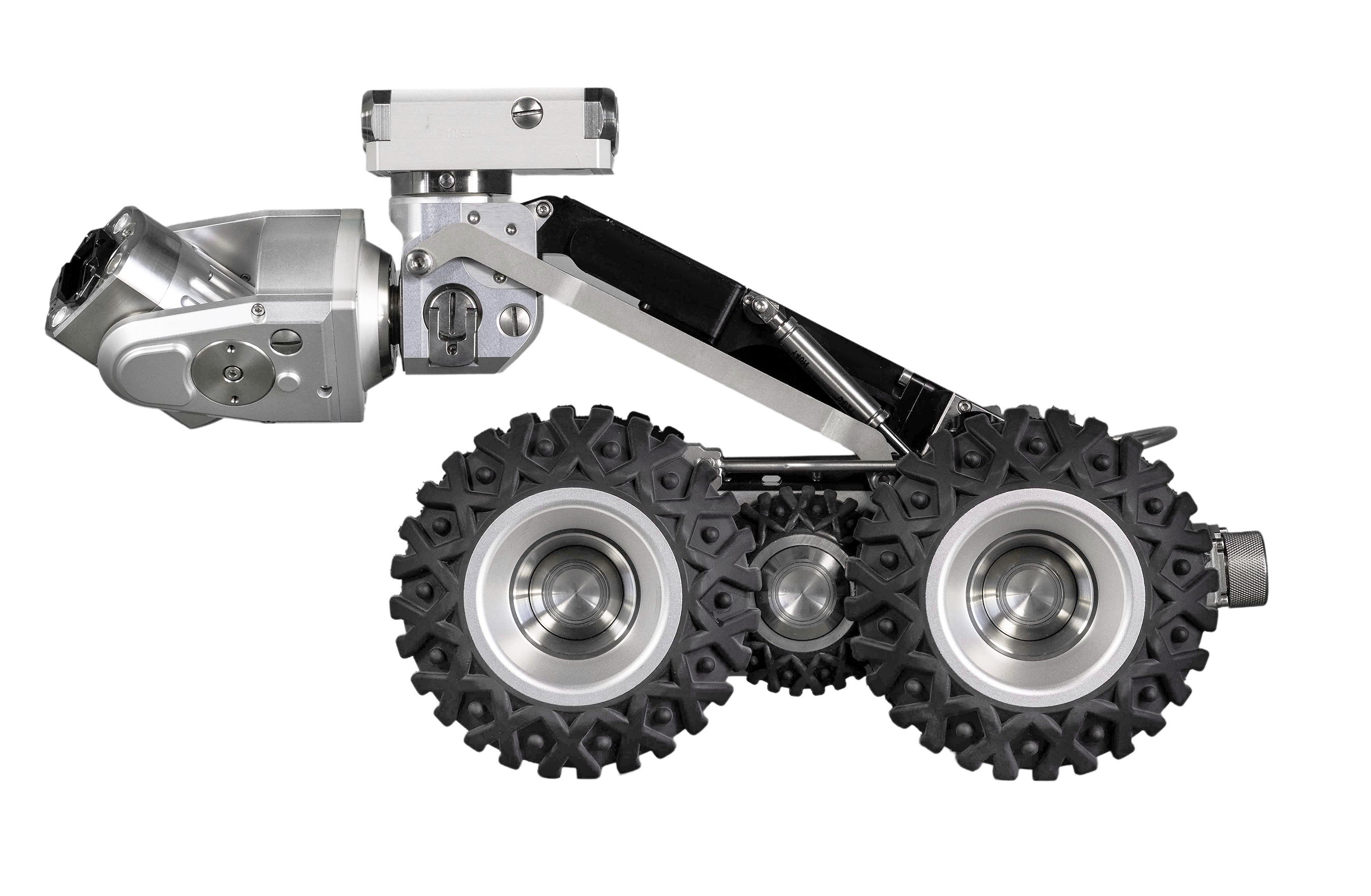

ROVION is built for any challenge

When you choose ROVION HD, you’re choosing unmatched productivity. With its advanced 6-wheel steerable drive, ROVION HD powers through obstacles, ensuring smooth inspections even in tough conditions. Designed with you in mind, it handles sizes from DN150 to DN2000 with ease. The patented Quick-Change Design minimizes setup time: Swap wheels effortlessly and keep your projects on track without delays to conquer even the toughest jobs with ease.

Pipe diameter

multifrequency location

Long-range traction

Perfect climbing properties

Well-maneuverable

Accessories for critical applications

Inclinometer measurement

High-speed inspection

Tilting protection

Crack-width measurement

Deformation measurement

Scalable lighting

Point diameter measurement

Camera centering

Waterlevel measurement

Visual inspection

catalog-based reporting

Strong in all conditions

and more

VC500

- Multi-functional, portable control panel

- Robust design and daylight readable, high resolution touch-screen

- Basis for operating software VISIONREPORT II with “WinCan Embedded Reporting“

DCX5000

- Core control unit for custom-built vehicles with ergonomic design – optimally prepared for all inspection requirements

- Touch-screen monitor for operating the system and for optimally monitoring the system status.

- Handy 3-axis-joysticks with push-function for precise control of all crawler and camera functions incl. zoom

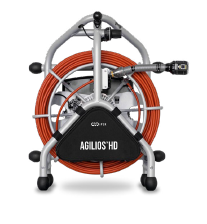

RMX200

- Maximum 200 m high-stability camera cable

- The E-box can be removed from the drum frame for future applications

- Adjustable brake

RAX300

- Maximum 300 m of extremely stable camera cable

- The winding speed and the tensile force can be regulated continuously

- Meter counter

RAX500

- Maximum 500 m extremely robust camera cable

- The winding speed and the pulling force is infinitely variable

- Meter counter

RX95

- Application range from DN100 up to DN200

- Powerful six-wheel drive (steerable)

- Location transmitter can be activated or switched over

RX130

- Application range from DN150 up to DN1000

- Powerful six-wheel drive (steerable)

- Quick Change Design (QCD) for a simple and fast setup

RX130L

- Application range from DN150 up to DN900

- Powerful six-wheel drive (steerable)

- Integrated, motor driven lifter

- Quick Change Design (QCD) for a simple and fast setup

RX400

- Application range from DN400 up to DN2000

- Powerful four-wheel drive (steerable), electrically operated 2-speed-gearbox

- Automatic lifter with sensor system for automatic camera centering inside the pipe

RAC50

- Smallest camera model built for the use in narrow pipe systems

- CMOS color camera

- Powerful homogenous illumination through LED lighting

PTC50

- Application range starts at DN100

- CMOS color camera

- Rotation and pan unit integrated in the camera head

RCX90

- Integrated laser to determine diameters and crack widths

- Powerful homogenous illumination through separately adjustable LED illumination for close and far ranges.

- Rotation and pan unit integrated in the camera head

RCX100HD

- More robust and reliable high-end pan-tilt-zoom camera

- Quick sleeve inspections and diameter measurements thanks to state-of-the-art motors

- 10x faster diameter and deformation measurements than with traditional laser methods

Simplify Inspections across DN400 to DN2000. Thanks to the Electric Elevator with Automatic Pipe Centering Sensors.

- Application range: From DN150

- Drive: Powerful 6-wheel-drive (steerable)

- Dimensions (WxHxD): Retracted: 384 x 126 x 117 mm

- Locating frequencies: 33 kHz/512 Hz/640 Hz (to be activated at choice, switching between frequencies)

Use the right joystick to move the crawler. The left joystick controls the camera. Adjust the camera angle and zoom. Use the touchscreen sliders to control the lights, lift, speed, and other functions.

Add notes to your inspections. Use observations, and data (speed, distance, camera angle). Customize your notes easily: drag and drop fields, save layouts, and add a logo.

Quickly add codes right on the screen. Type a few letters or choose from categories to find the right code. Add details as needed. Supports many code types, like PACP and WRc.

Quickly create PDF reports on the screen. Save them to your network or a USB drive. Choose from different report templates to show information clearly.

Measure flow, cracks, roots, pipe size, and angle of incoming lines with our advanced tools.

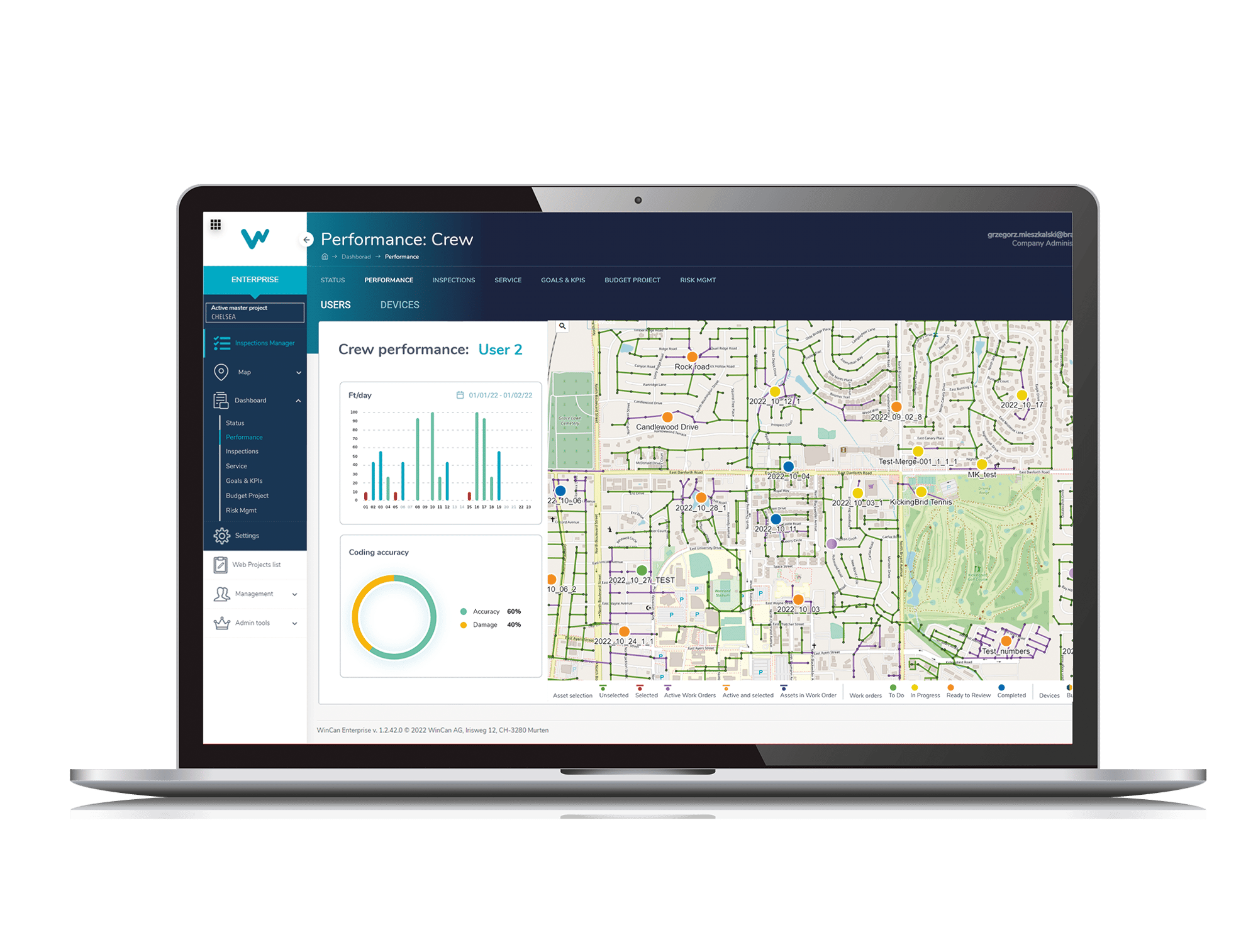

The ROVION controller connects to Wi-Fi. This lets you send inspections (data, videos, and photos) directly to WinCan Web for easy sharing, detailed analysis, and safe storage.

Use the right joystick to move the crawler. The left joystick controls the camera. Adjust the camera angle and zoom. Use the touchscreen sliders to control the lights, lift, speed, and other functions.

Add notes to your inspections. Use observations, and data (speed, distance, camera angle). Customize your notes easily: drag and drop fields, save layouts, and add a logo.

Quickly add codes right on the screen. Type a few letters or choose from categories to find the right code. Add details as needed. Supports many code types, like PACP and WRc.

Quickly create PDF reports on the screen. Save them to your network or a USB drive. Choose from different report templates to show information clearly.

Measure flow, cracks, roots, pipe size, and angle of incoming lines with our advanced tools.

The ROVION controller connects to Wi-Fi. This lets you send inspections (data, videos, and photos) directly to WinCan Web for easy sharing, detailed analysis, and safe storage.

Bewege den Fahrwagen mit dem rechten Joystick. Der linke Joystick steuert die Kamera. Passe den Kamerawinkel und den Zoom an. Steuere mit den Touchscreen-Schiebereglern die Beleuchtung, den Heber, die Geschwindigkeit und andere Funktionen.

Füge Deinen Inspektionen Notizen hinzu. Verwende Beobachtungen und Daten (Geschwindigkeit, Entfernung, Kamerawinkel). Passe Deine Notizen ganz einfach an: Ziehe Felder per Drag & Drop, speichere Layouts und füge ein Logo hinzu.

Füge Codes schnell direkt auf dem Bildschirm hinzu. Gebe ein paar Buchstaben ein oder wähle aus Kategorien, um den richtigen Code zu finden. Füge nach Bedarf Details hinzu. Unterstützt viele Codetypen, wie PACP und WRc.

Erstelle schnell PDF-Berichte auf dem Bildschirm. Speicher sie in im Netzwerk oder auf einem USB-Laufwerk. Wähle aus verschiedenen Berichtsvorlagen, um Informationen übersichtlich darzustellen.

Messe mit unseren fortschrittlichen Werkzeugen Durchfluss, Risse, Wurzeln, Rohrgröße und Winkel eingehender Leitungen.

Das VC500 Bedienpult stellt eine Verbindung zum WLAN her. So kannst Du Inspektionen (Daten, Videos und Fotos) direkt an WinCan Web senden, um sie einfach zu teilen, detailliert zu analysieren und sicher zu speichern.

Take Control

REMOTE

When working at a manhole, keep your attention on the task at hand. This remote control gives you complete command over all key crawler and reel functions, and it is included with every ROVION system.

MOBILE

The standard ROVION operator interface allows you to manage crawler and camera movements using joysticks, while a variety of additional functions are easily accessible through touchscreen controls.

ON PLACE

Designed for high-productivity settings, our desktop command center provides precise control, a full QWERTY keyboard, and ergonomic comfort for optimal performance.

Wheels

Carrier RCR1000

Auxiliary light RAL130

Auxiliary light RAL200

Auxiliary light RAL1000

Lifter RED200

Elevator extension

Laser profiler for RCX90 camera

Adapter for egg shaped pipes

Floating device RXF600

Temperature sensor RTS

Software Standard

Software Expert

Lateral Crawler

Push Camera Standard

Push Camera Expert

CCTV Van

Manhole Scanner

Video Nozzle